Sailmaker’s workshop

Our passion is sailing and this is a good reason to follow closely and make these textile wings last, as they take us to the end of the world. Multiplying the miles at sea obviously wears out the fabrics and the fittings of the sail, but you can do a lot of prevention and repairs yourself.

Acquiring the techniques of the master sailmaker is the guarantee of autonomy in case of tear but it is also to have a craft knowledge very pleasant to implement.

DAY 1 - 9 AM - 12.30 AM

Welcome of the participants / Coffee

Module 1 - Discovery of sails and materials.

Types of materials that constitute the sails. (Materials, manufacturers)

The choice of fabrics, cut and equipment for the long cruise.

How to evaluate the wear and tear of a sail? Diagnosis before purchase or before preparation for departure?

The details of manufacturing and assembly of a quality sail.

11 AM - 12.15 AM

Introduce the master sailmaker's tools

Safety gestures to avoid injury

Practical work 1

Cut a spreader reinforcement with a cutter.

Install correctly an anti-scraping protection.

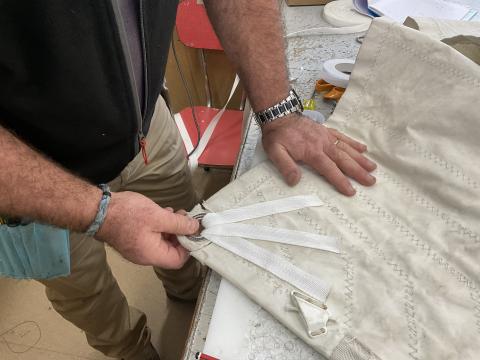

To strap a slider

2 PM - 4.15 PM

Practical work 2

Making a dog ear

Sew a leach line blocker

Repairing a clew with straps

4.15 PM - 5.15 PM

Choice of breeze sails

Type of rigging and adaptation to the needs of long distance sailing

Specificity of catamarans without the possibility of a drop stay.

Storm bags: feedback from use

Swedish mainsail. How to install it?

Staggering the reefing bands.

Installation of a removable stay. Safety, comfort and performance.

Technical specifications: Assembly, load transfer, storage chainplates, turnbuckles or hoists.

Made to measure deck bags for breeze sails

DAY 2

8.45 AM - 9 AM

Choice of downwind and light air sails.

Code 0, 1, 2 etc, gennaker, parasailor, sort out all the existing sails and their use

Choice and use of socks for downwind sails

Choice and use of flat drum furlers

10 AM - 12.15 AM

Practical work

Locking a slat gusset

Repair of a slat gusset with insertion of an internal reinforcement strap

Repairing a bolt rope tear with a strip of straight wire

LUNCH BREAK

2 PM - 3.30 PM

The basics of rigging control.

Explain the checklist of verification

Protecting and lubricating

Rigging adjustment.

Link between good rigging adjustments, efficiency and durability of sails

Sail trimming

Barber hauler, short sheet, cunningham

3.30 PM - 3.45 PM

Repair a tear in the middle of a fabric panel. Understand the mechanical stress of the fabric.

Repairing a tear on a spinnaker.

3.55 PM - 5 PM

Preparing your sailmaker's kit

Choosing a sewing machine for the trip

Sails and rigging checklist at your stopover